Understanding Reloading Presses

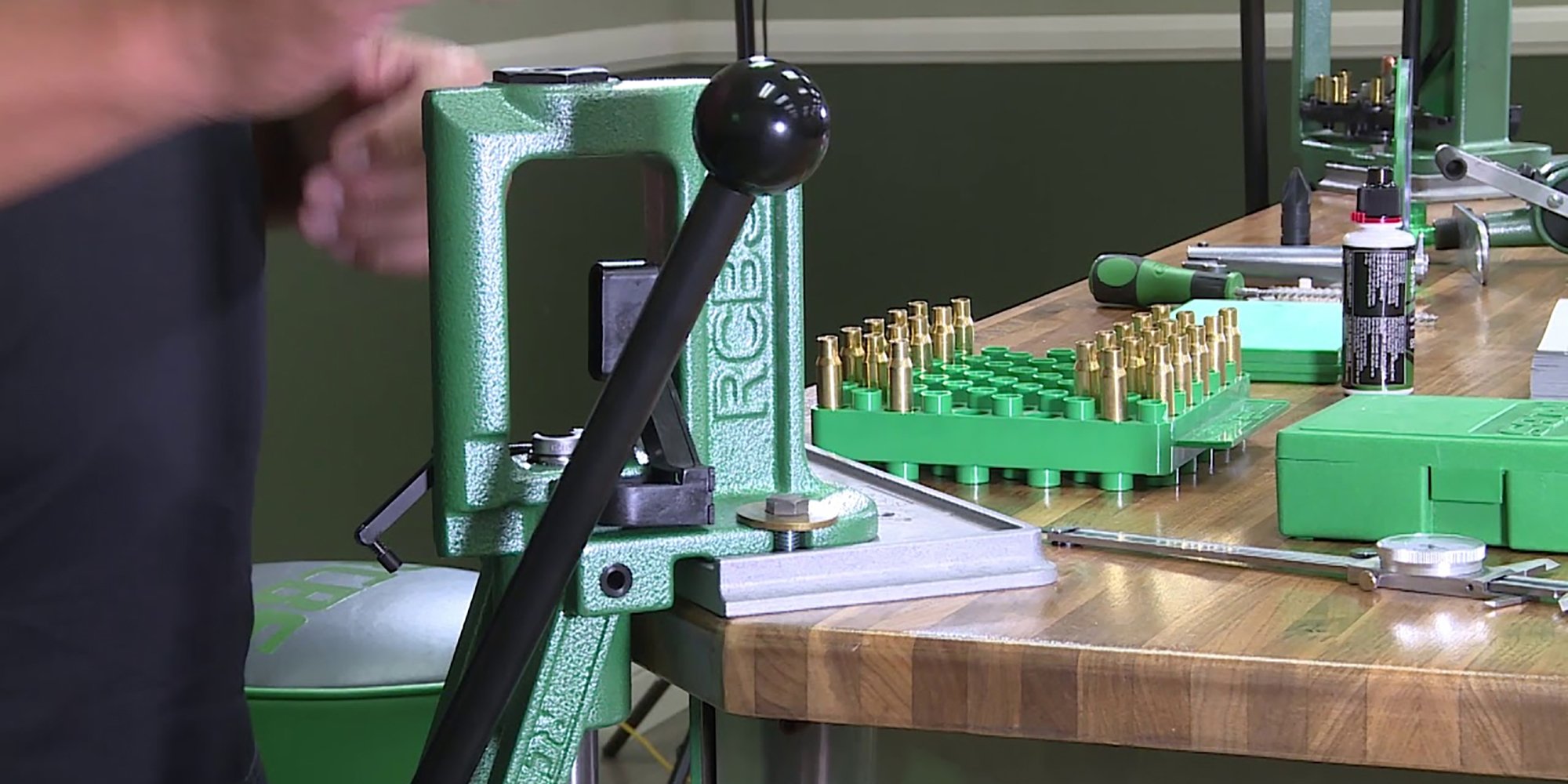

The reloading press is an ideal place to start when it comes to building a reloading station. It is a required component that performs a variety of functions during the reloading process. In essence, a reloading press works by using mechanical advantage and leverage to press two components together. Throughout the reloading process, a reloading press may be used for any of the following:

- Pressing a bullet into the casing.

- Pressing a new primer into a primer pocket.

- Pressing a brass case against a decapping pin to remove an old primer.

- Crimping the casing around a bullet.

- Opening the mouth of a casing with an expanding die.

- Pressing a casing into a resizing die.

While some of these steps can be achieved with different pieces of equipment, a reloading press is a versatile, multi-functional tool that can do all of the above tasks.

What Type of Press?

Within the world of reloading presses, there are three different options to choose from: single-stage presses, turret presses, and progressive presses. These different options provide different functionalities, which are outlined below:

Single Stage PRess

Single-stage presses are the easiest to use, in both setting up and learning the fundamentals of the reloading process. They require very little adjustment compared to the turret and progressive presses, and are generally the most cost-effective presses on the market. For these reasons, single-stage presses are often suggested for the novice or first-time reloaders. This being said, single-stage presses do have the slowest rate of production. Experienced reloaders typically opt for turret or progressive presses when reloading large volumes of ammunition. Even as you may progress through the levels of reloading experience, your single stage press will still have a home on your reloading bench. A well-built single-stage press will last a lifetime (and then some), and is perfectly capable for smaller batches of ammunition.

Turret Press

Generally seen as a ‘step above’ single-stage presses, turret presses are the ideal solution for reloading larger batches of ammunition. They are more expensive and have more moving parts than single-stage presses, but a decently experienced reloader can perform upwards of 200 rounds per hour when using a turret press. These types of presses allow the user to mount multiple dies on the press at one time through the use of a rotating ‘turret’. Users can simply rotate the turret of the unit to the next die and proceed without needing to interchange the die. On some models, it may be the cartridge that moves from die to die during the reloading process. Many turret presses also feature an extra port for easily mounting a powder measure, again increasing the overall rate of production.

Further, turret presses allow reloaders to keep several of the turrets set up at one time, for each cartridge that they regularly reload. The turret can simply be placed onto the press as a whole piece, instead of individually changing each die.

Progressive Press

Progressive presses are largely intended for experienced reloaders who need a maximum-volume capacity. Typically, progressive presses can output around 500 rounds per hour. Most progressive presses will have four or five die stations that can hold all the dies needed for the reloading process. They also can feature powder measures and specialty, niche dies to add even further capability. Progressive presses are the most expensive type of reloading press and should not be used to produce small batches of ammunition. They usually require time and maintenance investments as well to set up and continue smooth operation. Specifically, when switching between calibers, progressive presses will require extra adjustments and set up time, due to their expanded capability. Again -- we only recommend progressive presses for the most advanced users.

O-Frame vs C-Frame

Presses may also be categorized by the letter of the alphabet that they most resemble -- typically “O”, “C”, or “H”.

O-Frame presses feature heavy steel that encloses the single die. They are sturdy and allow the user to apply more force (which can be handy when working with very large calibers), but the extra metal supports may be obtrusive for some users.

C-style presses don’t allow for quite as much force but are suitable for most standard applications. The C-shape allows the reloader more room to insert bullets into cartridge mouths.

H-Frames are generally only found on shotshell style presses.