Case Prep Tools

When a rifle cartridge is fired, the case in the chamber is violently slammed forward and backwards. It expands against the chamber walls and is drastically misshapen by the shockwaves and vibrations that occur throughout the firearm. The best way to ensure shot-to-shot accuracy in modern firearms is to create more uniform ammunition, which is one of the leading motivations for handloading ammunition. And to make consistently shaped ammunition, we begin with case preparation.

Case preparation is generally the initial phase of reloading ammunition. It is a set of operations through which cases are produced that are uniform as possible in every aspect. In this section of our reloading guide, we will take you piece-by-piece through the tools that you will need to properly prepare cases for reloading. All of these tools can be used with cases that are new or cases that have been previously fired and cleaned.

Primer Pocket Uniformer

Variations in primer pocket depth can alter the effect of the firing pin’s impact. Many reloaders choose to recut their primer pockets to ensure a consistent ignition. To do this, they use a primer pocket uniformer to cut the primer pockets square to the case head (and to a uniform depth). A primer pocket uniformer is a hardened steel or carbide cutter that can either be used manually or attached to a cordless screwdriver through the use of an adapter. Many experienced reloaders suggest uniforming primer pockets every time a case is reloaded.

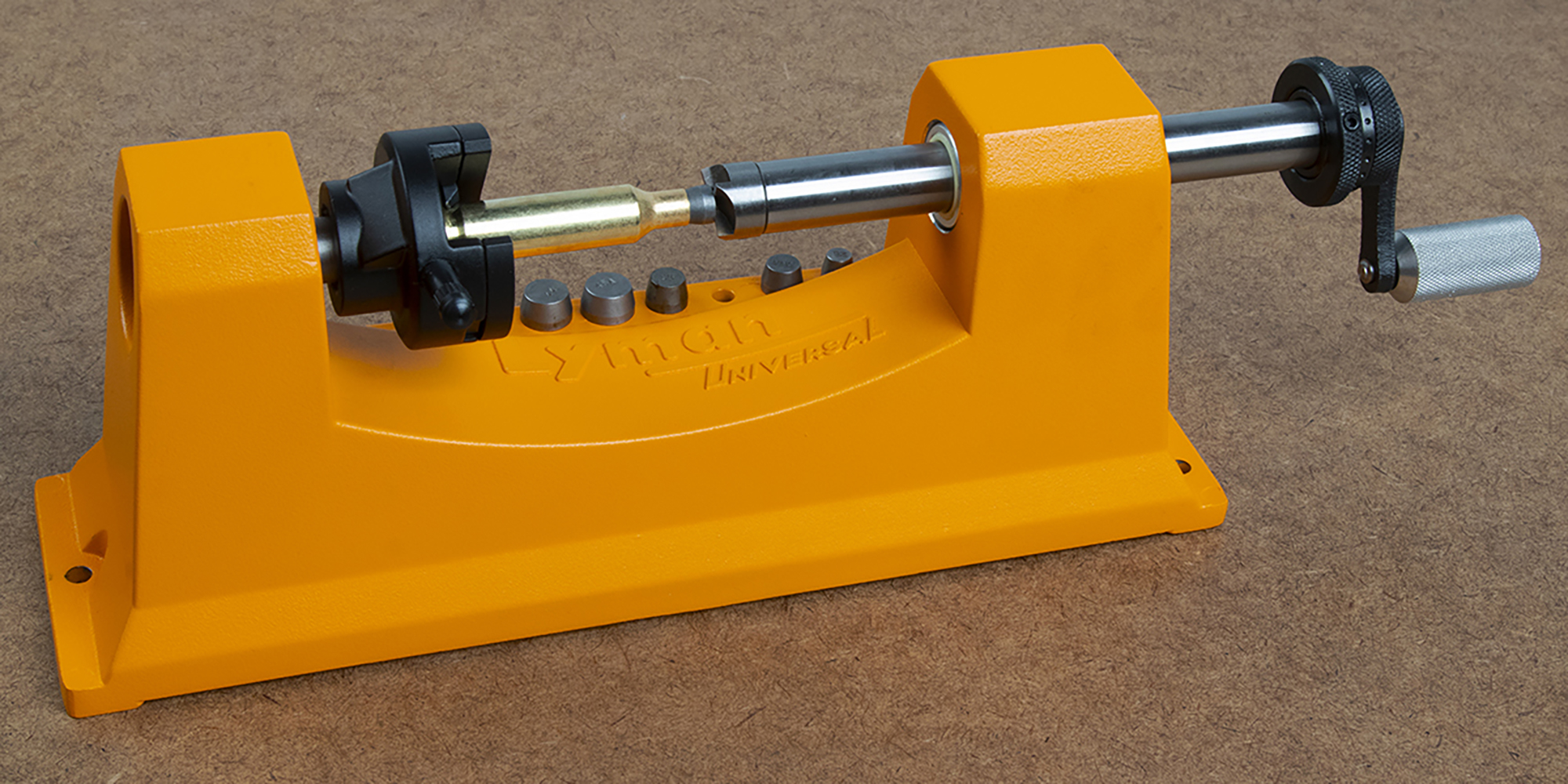

Case Trimmer

Case trimming is one of the most important parts of the case prepping and reloading process. When you fire a round, the brass case slightly increases in length from the pressure of firing. Overly-long cases can easily get jammed into the case mouth shoulder in the chamber of a firearm. This will prevent the case neck from expanding as it needs to properly release the bullet. Cases should be measured for length every time they are being reloaded to ensure consistent performance and eliminate unnecessary variables. Case trimmers are usually simple tools that consist of a mandrel to fit inside of the case mouth, and a cutter that will trim the neck when either the case or the cutter is rotated.

Chamfering and Deburring Tool

Often, the trimming process will result in a raised burr inside or outside the mouths of the case. To ensure proper case neck alignment and clearance in the chamber, you must remove this burr. A chamfering and deburring tool is a simple hand tool that features inside and outside cutting blades at opposite ends. Typically, the same tool will perform both chamfering and deburring.

Lubricants

When loading pistol cases, reloaders can use stick-free carbide dies which make lubricants unnecessary. However, for most rifle ammunition, it is necessary to lubricate your brass cases before using them with a reloading die to prevent them from getting stuck in the die. With insufficient or no lubricant, the pressure exerted by the reloading die will cause the malleable brass case to stick inside the harder steel die. On the other hand, too much lubricant can cause a similar problem. By using excessive lubricant, you risk creating a vacuum inside the die, which will suction the brass case to the steel. There are several different lube options that are available to reloaders.

Lube pads are a popular option for reloaders. Lube pads are made of spongy, absorbent foam. The user rubs lube onto the pad, and then simply rolls the cases across. Most large manufacturers of reloading supplies make lubricants that work well with lube pads. This is a simple and efficient way to consistently apply lube to cases. However, when reloading large amounts of ammunition, this may be a tedious method of lubricating cases.

For high volume reloaders, spray-on lubricants are a popular solution. To make this process even quicker, many reloaders use a lube rack.

Particularly demanding shooters often use Sizing Die Wax to lubricate cases. It offers very high lubricity and wipes off fairly easily with just a paper towel or a rag. Sizing wax is applied naturally, unlike lube pads or spray lubes. Users simply rub some sizing wax onto their fingers and it is transferred to the cases by handling them. This makes it best for lower-volume reloaders.

Dry neck lube is another option. To use dry neck lube, simply dip the neck of the case into the container. This lube allows the expander ball to work smoothly in the case neck. Dry powdered lube also will not contaminate your powder, so there’s no need to remove it from the case neck once finished.

Lube Rack

A lube rack is a polymer block that holds cases upright as they are sprayed with lubricant. Through the use of a lube rack, reloaders can quickly spray large amounts of cases with spray-on lubricant.

Case Cleaning Tools

Cleaning brass before reloading is very important. It’s crucial to remove any dirt or debris before turning brass cases into range-ready ammunition. There are three ways to clean your brass: vibratory dry media tumbler, the ultrasonic cleaner, and the stainless steel pin/liquid media rotary tumbler.

Dippers

Vibratory dry media, also known as a vibratory tumbler, is one of the most popular case cleaning methods for reloaders. Vibratory tumblers are simple and effective. The tumbler itself is a plastic bucket or tub that sits on an electric motor. Into the tub, the user pours his or her dirty brass and dry cleaning media -- usually ground corn cob or walnut shell. The motor runs to vibrate the entire tub, essentially automatically scrubbing the cases with the dry media. Vibratory tumblers can be quite loud and often take a few hours to finish cleaning the brass, so most reloaders try to perform this step out of earshot. Once the tumbler is finished, the user pours the contents of the tub out into a sifter to separate the media from the brass. After this step, each case needs to be turned upside down to dump out any media that gets caught inside. Check the flash hole of each case, as media can often wedge inside the flash hole. This media should be removed. Lastly, any excess media dust needs to be wiped away from the outside of each case.

Dry media will need regular replacing, depending on how rigorously and often it is used. The particles of dry media break down into dust, which can be very messy. This is one of the downsides to using dry media for cleaning brass.

Vibratory tumblers come in many different sizes, with differing limits for cleaning capacity. Tumbler capacities are typically expressed as “x number of y caliber cases”. For example, you may find a tumbler that has a capacity of 1000 9mm cases. Generally speaking, the more cases you clean in a tumbler, the longer it will take. Dry media tumblers will not clean primer pockets.

Ultrasonic Cleaners

In a sense, ultrasonic cleaners work very similarly to vibratory dry media tumblers. In ultrasonic cleaners, the media is a liquid and the vibration only occurs on a near-microscopic level. The liquid media essentially acts as a soap, while ultrasonic waves cause the movement. This loosens and lifts away debris, but it does not polish the brass. Cases cleaned in an ultrasonic cleaner will come out clean, but dull. That said, ultrasonic cleaners do clean the inside of brass cases, whereas dry media tumblers do not.

Ultrasonic cleaners are relatively fast and quiet, too. With an ultrasonic cleaner, brass is cleaned within minutes instead of hours. These devices also operate with only a quiet buzzing. If the cases’ primers are removed before entering the device, ultrasonic cleaners will even clean the primer pockets. The wet media used in ultrasonic cleaners is usually mixed with water at a 40:1 ratio, and can be reused over the course of several batches. Ultrasonic cleaners are typically built with removable baskets that can be easily used to lift out the cleaned brass. Then, the media can be strained to remove particulates and used again. When removing cases from the ultrasonic cleaner, it’s helpful to rinse them in distilled water to remove the cleaner residue and avoid water spotting.

Some handloaders choose to clean their cases in the ultrasonic cleaner first, rinse and dry the cases, and then put them in the vibratory tumbler. This way, they come out fully clean and have the brightness of a new case.

In addition to cleaning brass, ultrasonic cleaners can also clean gun parts. Larger-capacity ultrasonic cleaners can be used to clean an entire pistol frame -- you will need to use a different wet media cleaning solution, but these are readily available on the market.

Stainless Steel Pin/Liquid Media Rotary

Of the three case cleaning devices we’ve listed, this is the newest on the market for handloaders. Rotary tumblers can be purchased with small stainless steel pins and a liquid solution for cleaning brass. These two components work together within the tumbler to ensure a more robust cleaning.

The construction of a rotary tumbler is fairly simple. They are hollow drums, turned by electrically powered rollers. Small stainless steel pins and the cases to be cleaned go inside of the drum. Then, a liquid cleaning media is added to the drum. For one to three hours, the rotary tumbler automatically cleans the cases. By combining wet and dry media, rotary tumblers are able to clean the inside and outside of the cases, as well as the primer pockets. It also polishes the cases, unlike ultrasonic cleaners.

When the cleaning process is over, sifters are generally included to separate the media from the cases. Unfortunately, the liquid media is not reusable.

Drying Your Cases

If cleaning with wet media, your brass cases will need to be dried. There are several ways to accomplish this. A standard food dehydrator will quickly and effectively dry your brass cases. It can be used to dry a large number of cases at once and is a very cost-effective method. Some reloaders may choose to use a low-temperature oven. You can also simply air-dry your cases. You can also turn your cases upside down on a drain rack and dry them with a hair drier, which is a quick method of drying a large number of cases. Some ultrasonic cleaners have a rack built into the top for this very purpose. Aside from the time that each method takes, none of these options are particularly advantageous over another.