Knife Steel Chart

Finding the perfect knife requires much more than finding a cool design. The quality of a knife is determined by the quality of it's steel, and how well that steel will perform for the intended purpose. Steel performance is based on four attributes: Edge Retention and Wear Resistance, Toughness, Ease of Sharpening, and Corrosion Resistance. The following knife steel charts will help you evaluate steel quality—and knife performance—based on these attributes.

Steel Factors for Comparison

Steel quality is commonly determined by four performance attributes. These including Edge Retention and Wear Resistance, Toughness, Ease of Sharpening, and Corrosion Resistance. While each of these attributes is important, you'll want to evaluate each based on the intended use of your knife. If you'll be using your knife to cut bone, edge tention and toughness are going to be important attributes. If you're using your knife in a saltwater environment, corrosion resistance should be high on your list.

Edge Retention and Wear Resistance

Edge retention is usually classified as the steel’s ability to maintain a sharp edge during use. Multiple factors can come into play that will affect how well the edge remains sharp. This causes most to focus on how well the steel resists abrasions during cutting.

This ties into wear resistance by measuring how long it takes for the steel to wear down from outside forces. The resistance comes from the development of carbides, which are hard particles formed from the bonding of carbon with elements like Vanadium or Tungsten.

These carbides can make the steel brittle which will decrease the steel’s toughness despite increasing the edge retention. A steel’s edge retention has to deal with things like deformation, corrosion, micro-chipping, and general wear. This makes determining edge retention harder to do, especially when other factors from the forging and knife making process are added.

Toughness

A steel’s ability to resist chipping or breaking is the steel’s toughness. This mitigates heavy impacts, like those encountered by cleavers or chopping knives. Toughness comes from the steel having less hardness, resulting in comparatively softer steels.

Steels with relatively high toughness usually cannot have high levels of wear resistance and edge retention. The factors needed for toughness and those needed for edge retention are on opposite ends of the spectrum unless you are using expensive metals in your alloy.

Prioritizing whether you need a knife to be tough or have high edge retention will determine which steel you’ll select.

Ease of Sharpening

How easy it is to sharpen a knife is determined by several factors: the wear resistance of the knife, the edge thickness, how dull the knife is, the heat treatment style/quality, and the method of sharpening.

Wear resistance will be the major factor when sharpening, but if you have trouble sharpening certain knives, other factors may be impeding the process. A high wear resistance will indicate that a steel will be harder to sharpen since sharpening is abrasion and wear resistance is how well the steel resists abrasion.

Corrosion Resistance

Corrosion can cause damage to your knife by causing pitting, dulling and other structural damage. This can be from the knife getting stained, rusting, or developing a patina.This means a knife that is resistant to corrosion will last longer in a highly corrosive environment than a steel prone to corrosion.

Stainless steel (those steels with 10-20% chromium alloys) are better at resisting corrosion, but will eventually corrode or rust in the right environment. High levels of chromium do not always indicate a high level of corrosion resistance and comes down to the processing of the steel and how much chromium is available on the surface metal.

Most stainless steels will buy time for you to be able to clean the knife properly or allow for less frequent maintenance.

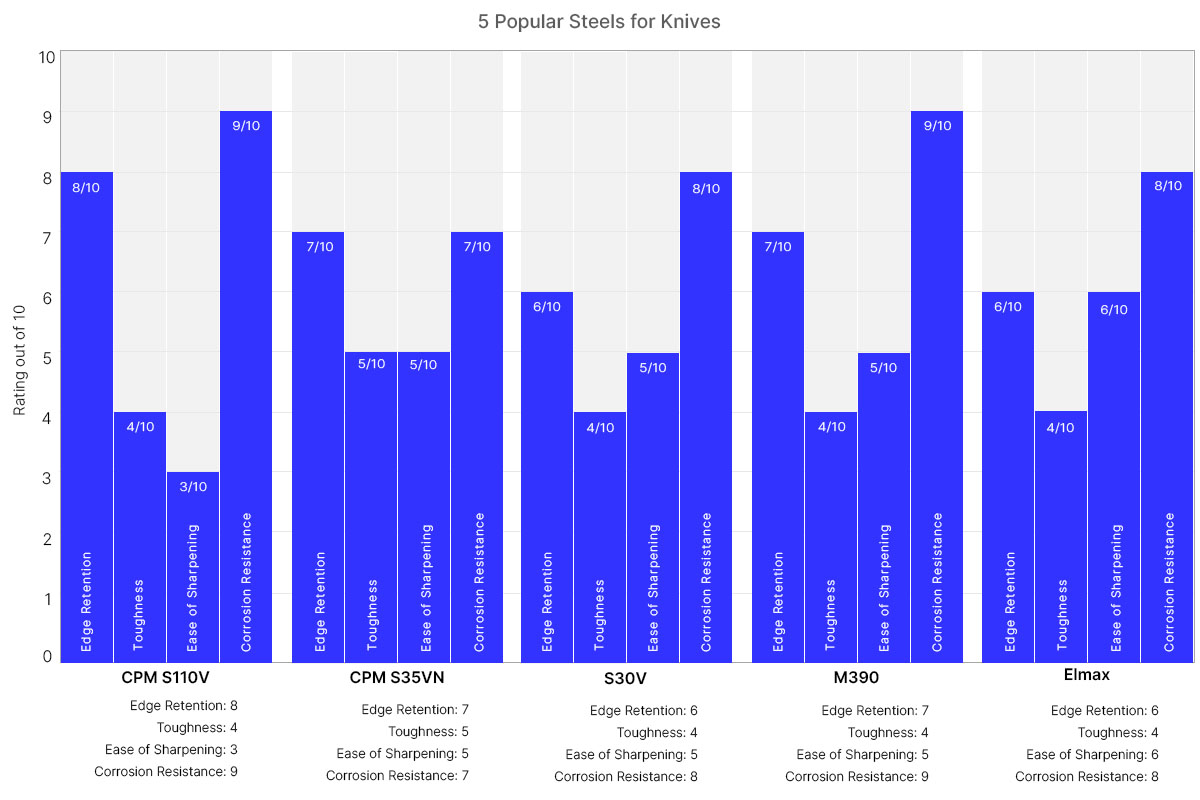

5 Popular Steels for Knives

There are a lot of high quality steels used for knife making. The following are a few of the more popular steels used for producing top performing knives.

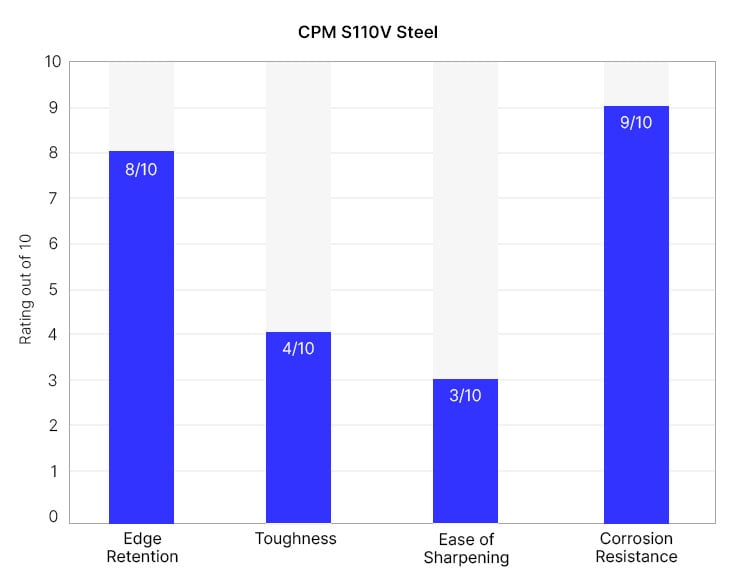

CPM S110V

Perfect for knives that see a lot of use, CPM S110V is designed for edge retention and corrosion resistance. This steel is not as commonly used with most examples being from Spyderco.

Patented in 2007, S110V features 15.25% chromium in the alloy for better corrosion resistance. The original percentage was 14% but even then the chromium created an issue of carbide formation. Since vanadium and chromium can work together to produce chromium carbides, less vanadium carbides formed impacting long term wear resistance.

This problem was solved with the introduction of niobium. Using niobium resulted in harder carbides and reducing the number of chromium and vanadium carbides. Molybdenum was added to help reduce pitting and increase corrosion resistance.

S110V would have a composition change around 2010, decreasing the niobium and increasing the chromium to the current 15.25%. The current theory for this change was to reduce manufacturing hassles while increasing the safety of production.

| Edge Retention | 8/10 |

| Toughness | 4/10 |

| Ease of Sharpening | 3/10 |

| Corrosion Resistance | 9/10 |

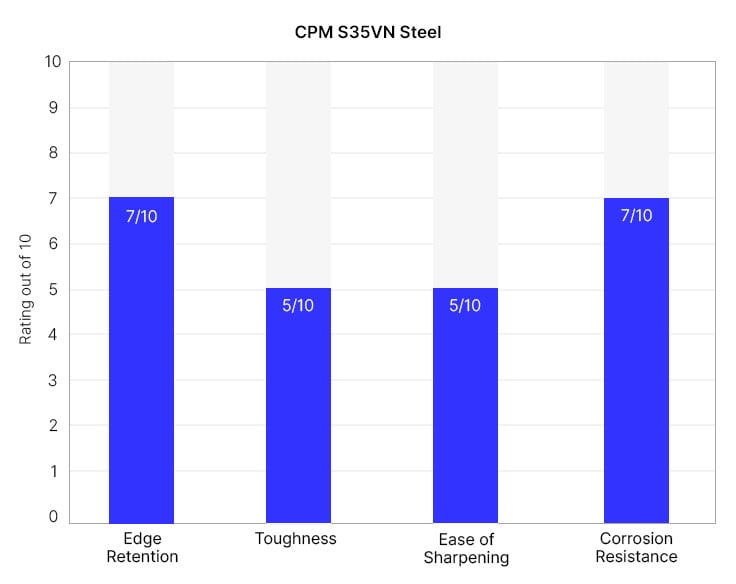

CPM S35VN

CPM S35VN was designed by the legendary knifemaker Chris Reeve and developed by Maria Sawford before being released in 2009. It took CPM S30V and added 0.5 % niobium for easier machining and sharpening. These two steels are functionally the same for the end user, but make blades easier to manufacture for large producers.

The major differences between S35VN and S30V are a reduction in vanadium content and a lower level of added nitrogen. This increased the overall toughness of the knife, lowered edge retention, but made S35VN as easy to machine as S30V. This makes S35VN a very well rounded steel that doesn’t excel in any singular factor.

| Edge Retention | 7/10 |

| Toughness | 5/10 |

| Ease of Sharpening | 5/10 |

| Corrosion Resistance | 7/10 |

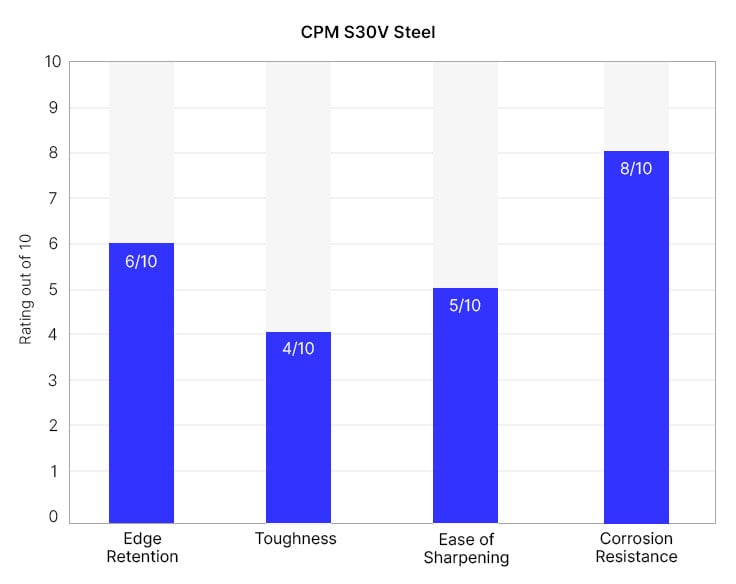

CPM S30V

This is a common steel used in most EDC knives and was released in late 2001. CPM S30V was developed to meet the needs of knife makers like Chris Reeves. This resulted in a better steel than what was currently being used (BG42 steel).

The steel was designed to hold a good edge, resist corrosion, and balance ease of sharpening and durability. Additionally, S30V has a lower production cost, making it an affordable option for most knife designs, and can be properly heat treated with common equipment.

The primary reason this steel is one of the most common knife steels is the development process. It was tailor made for the needs and wants of custom and industrial knife makers. This resulted in a well rounded steel that can be overlooked due to its high usage.

| Edge Retention | 6/10 |

| Toughness | 4/10 |

| Ease of Sharpening | 5/10 |

| Corrosion Resistance | 8/10 |

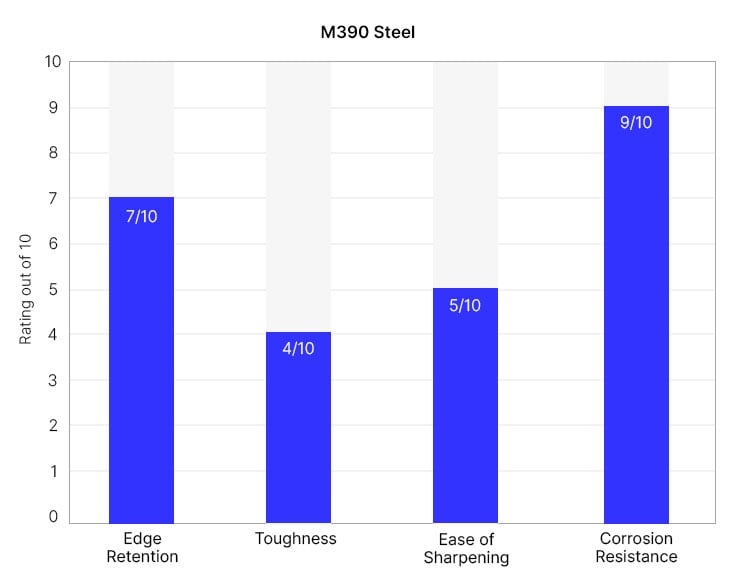

M390

Developed in the late 1980s, M390 uses powder metal technology to combine chromium, molybdenum, vanadium, and tungsten into the alloy for more efficient use of the available chromium. What this produces is a steel with great edge retention, very high corrosion resistance, and moderate durability that is harder to sharpen. CPM 20CV and CTS204P are almost identical with M390, but M390 is the most likely to be used internationally.

M390 was originally designed for use in plastic manufacturing and it wasn’t until 1999 when it started to be used in custom European knives. It was copied by Latrobe Steel and Carpenter Steel and used by SOG as CPM 20CV up through the 2000s. M390 and its equivalents would truly gain popularity in 2010 with its adoption by Kershaw and Benchmade.

| Edge Retention | 7/10 |

| Toughness | 4/10 |

| Ease of Sharpening | 5/10 |

| Corrosion Resistance | 9/10 |

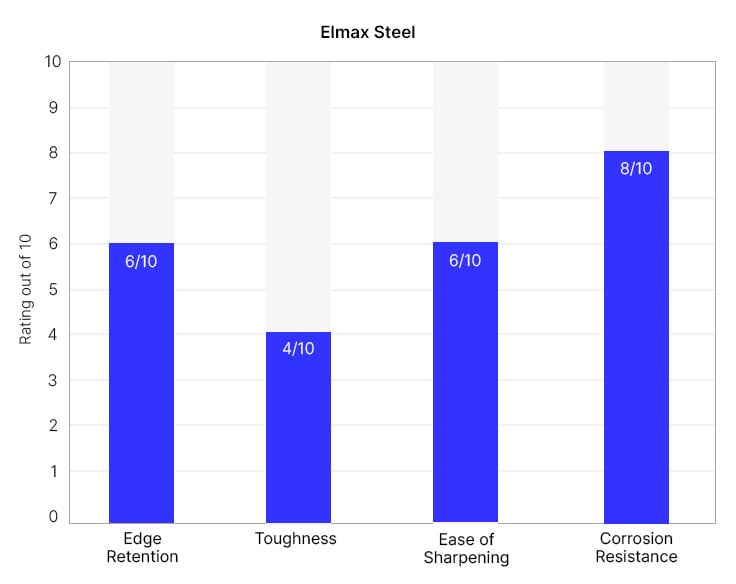

Elmax

Elmax steel has a very fine grain structure compared to M390 which makes it tougher and more wear resistant. This comes with slightly less corrosion resistance.

Elmax shares an origin with M390 as the manufacturer was primarily focused on producing a steel that was good for plastics processing. But like most durable, hard steels it was eventually adopted by knife manufacturers who wanted cutting tools that would last longer, with less maintenance.

| Edge Retention | 6/10 |

| Toughness | 4/10 |

| Ease of Sharpening | 6/10 |

| Corrosion Resistance | 8/10 |

US Manufacturers

Crucible Industries Steel

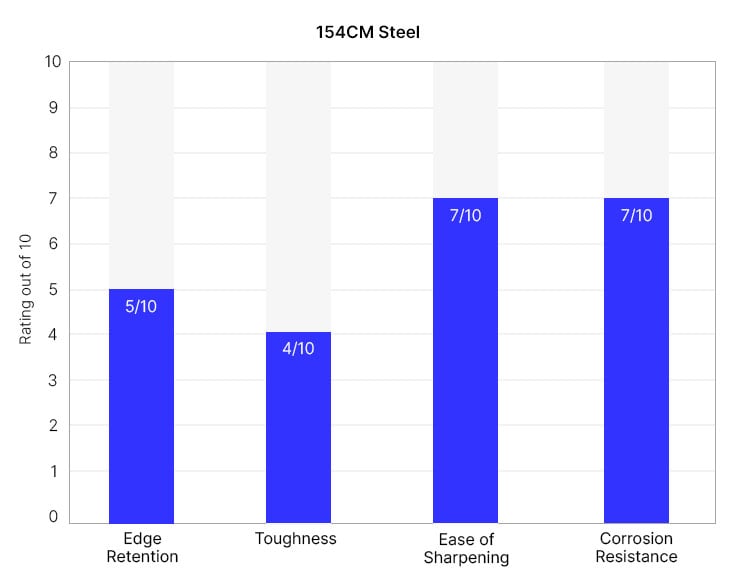

154CM

Easily sharpened and very resistant to corrosion, 154CM is used by many top manufacturers for quality pocket knives. This steel is like 440C but with less chromium. Closer to a perfect average in all factors, this steel is good for long term use, especially with proper care.

| Edge Retention | 5/10 |

| Toughness | 4/10 |

| Ease of Sharpening | 7/10 |

| Corrosion Resistance | 7/10 |

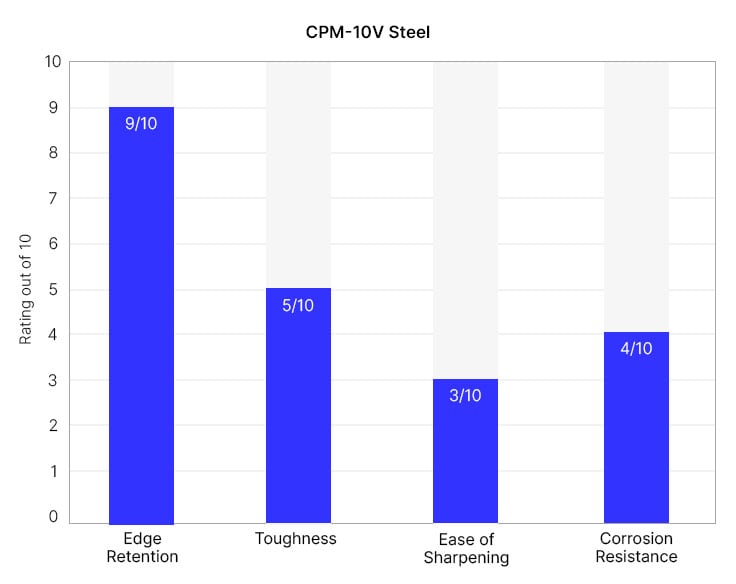

CPM-10V

While this steel is Crucible’s equivalent of K390, it is a relatively rare steel on the market. With a high edge retention and a decent durability, this steel is better for heavy cutting situations. However it is hard to sharpen and has below average corrosion resistance.

| Edge Retention | 9/10 |

| Toughness | 5/10 |

| Ease of Sharpening | 3/10 |

| Corrosion Resistance | 4/10 |

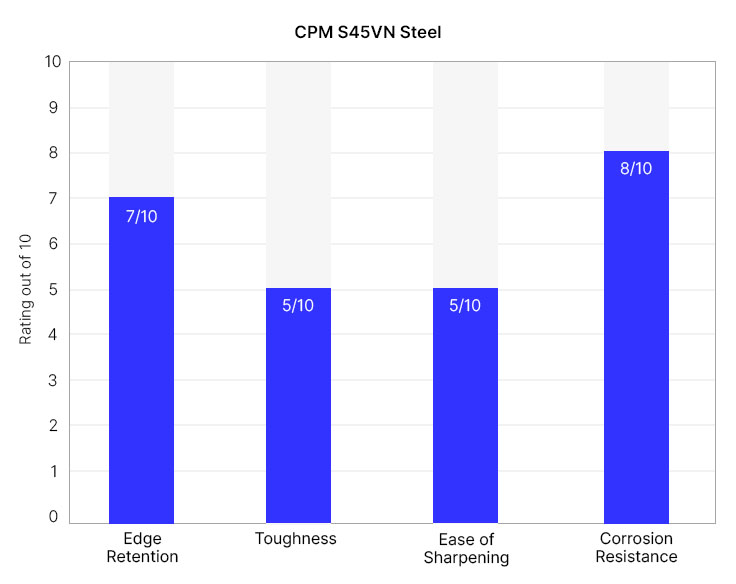

CPM S45VN

The primary difference between CPM S35VN and S45VN is a higher chromium content in S45VN. This provides slightly better corrosion resistance to the base steel. Introduced 2019.

| Edge Retention | 7/10 |

| Toughness | 5/10 |

| Ease of Sharpening | 5/10 |

| Corrosion Resistance | 8/10 |

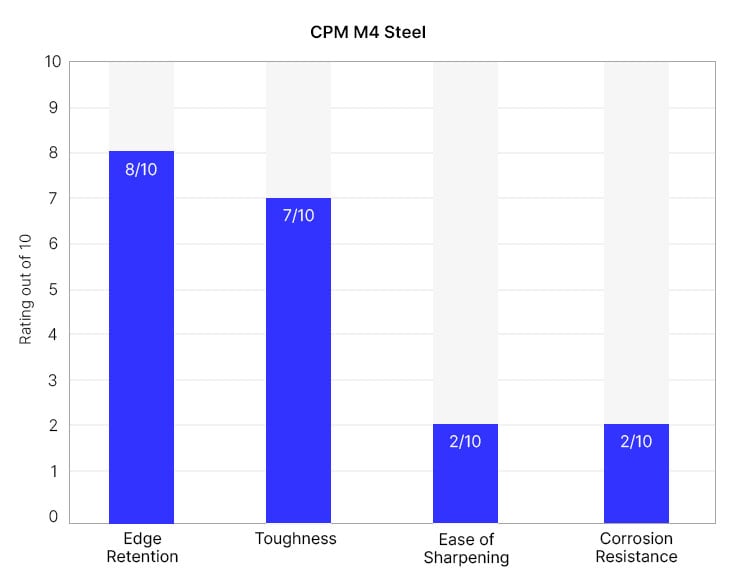

CPM M4

CPM M4 is one of the rare steels that has a combination of quality edge retention and durability. This comes from the high levels of molybdenum, vanadium, and tungsten paired with high carbon levels. This makes it incredibly good at cutting but very likely to corrode/patina without care. CPM M4 tends to be coated to prevent this, but coatings are a temporary solution.

| Edge Retention | 8/10 |

| Toughness | 7/10 |

| Ease of Sharpening | 2/10 |

| Corrosion Resistance | 2/10 |

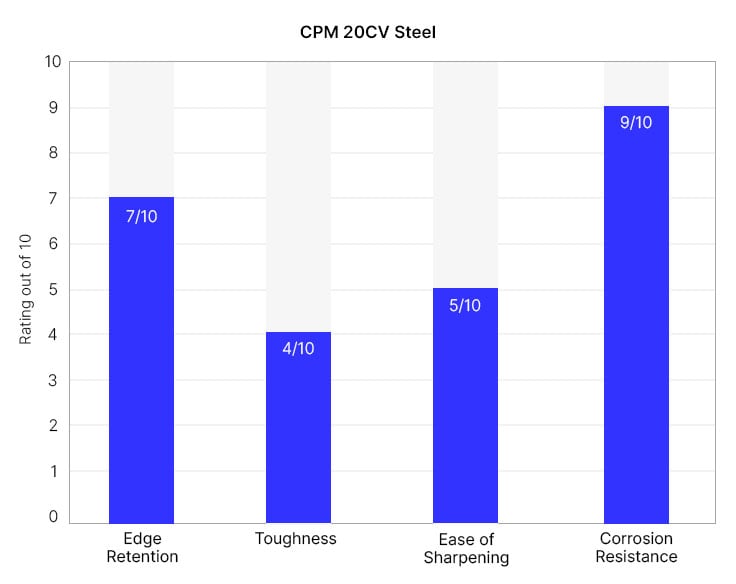

CPM 20CV

With its amazing resistance to corrosion and wear, CPM-20CV is the Crucible equivalent of M390 and very similar to CTS 204P. This powdered steel is marginally less durable than M390 but retains edges better. Benchmade and other high end manufacturers use CPM-20CV for some knife models.

| Edge Retention | 7/10 |

| Toughness | 4/10 |

| Ease of Sharpening | 5/10 |

| Corrosion Resistance | 9/10 |

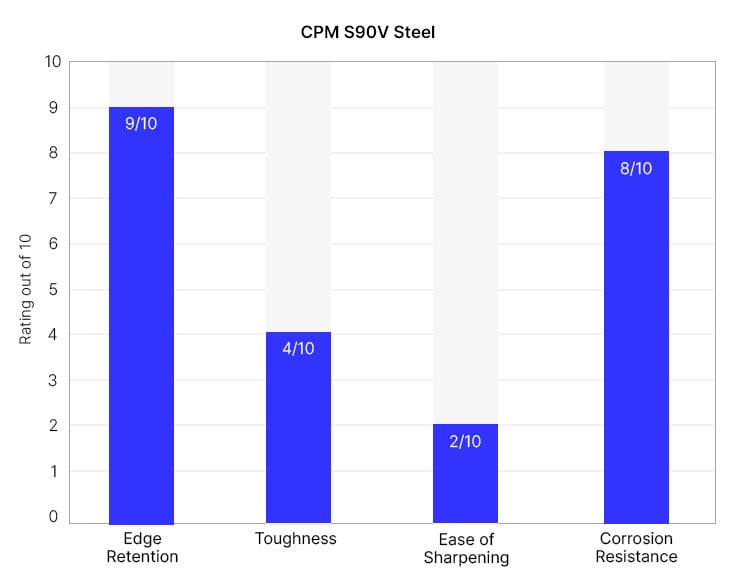

CPM S90V

Characterized by high edge retention and corrosion resistance, CPM S90V is a brittle steel that is not designed for large blades. The steel is very hard to sharpen and expensive. This is from the high vanadium content, which is three times higher than S30V or Elmax. The only steel similar to it for edge retention is S110V.

| Edge Retention | 9/10 |

| Toughness | 4/10 |

| Ease of Sharpening | 2/10 |

| Corrosion Resistance | 8/10 |

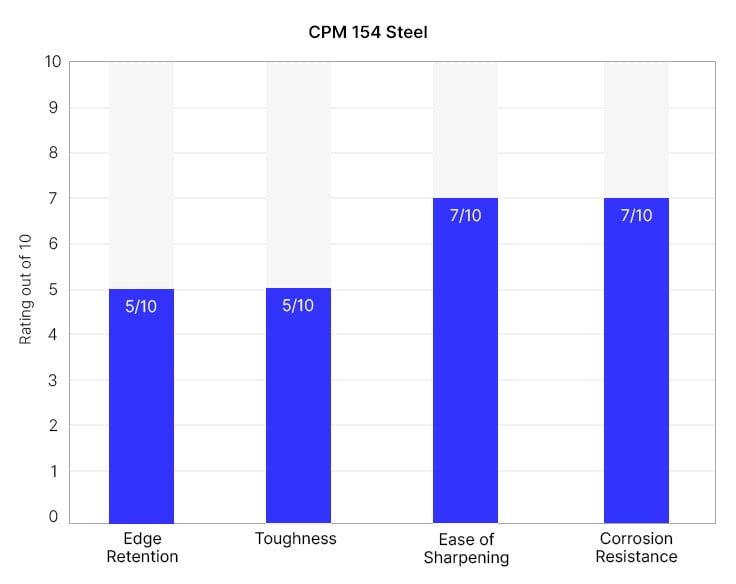

CPM 154

A chemical copy of 154CM, the CPM-154 has better edge retention and a much finer grain structure. This is a result of using particle metallurgy and allows for better control of the steel’s properties.

| Edge Retention | 5/10 |

| Toughness | 5/10 |

| Ease of Sharpening | 7/10 |

| Corrosion Resistance | 7/10 |

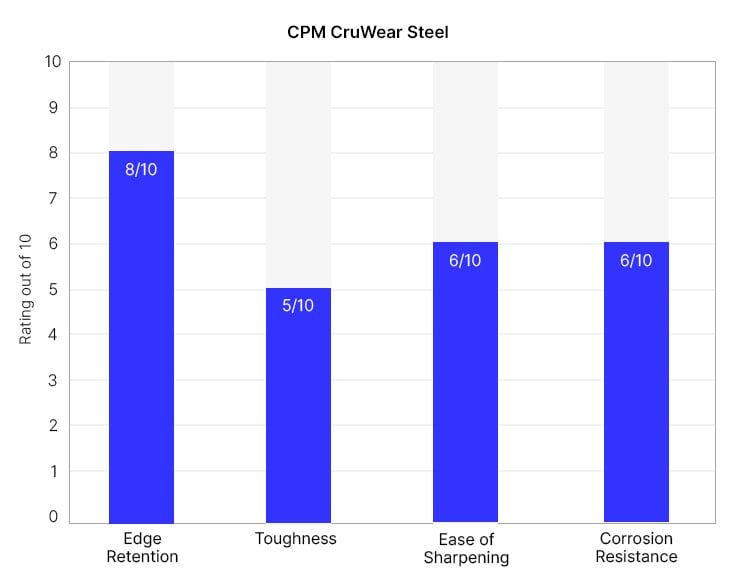

CPM CruWear

CruWear is the balance between CPM-3V and -M4 in terms of durability and edge retention. This is achieved by using higher levels of vanadium and tungsten while using less carbon and chromium. Vanadium carbides are harder than chromium carbides producing better hardness while the lower carbon levels make the steel less brittle. This high end steel is better used for hard use fixed blades.

| Edge Retention | 8/10 |

| Toughness | 5/10 |

| Ease of Sharpening | 6/10 |

| Corrosion Resistance | 6/10 |

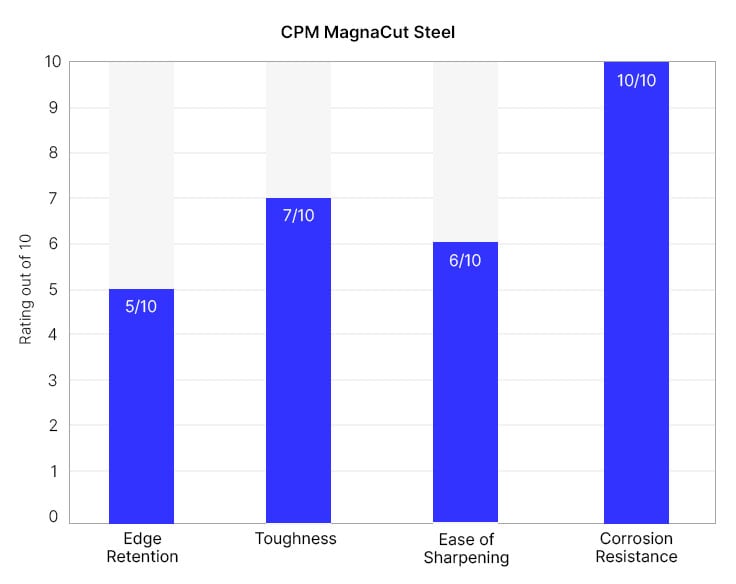

CPM MagnaCut

A newer steel from Dr. Larrin Thomas, CPM MagnaCut came onto the market in 2021. It features a low chromium content that is strategically used in the steel’s structure to maximize the chromium’s effects without trapping it in carbides. This results in great durability and corrosion resistance. Currently this is an expensive, premium steel.

| Edge Retention | 5/10 |

| Toughness | 7/10 |

| Ease of Sharpening | 6/10 |

| Corrosion Resistance | 10/10 |

Carpenter

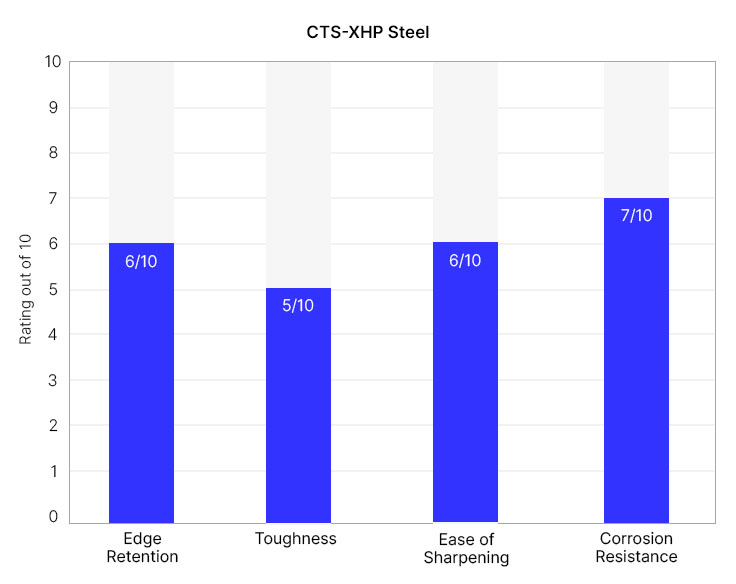

CTS-XHP

The CTS-XHP is a powder steel that is similar to D2 but with higher corrosion resistance. This “Stainless D2” can be heat treated to the higher ends of the Rockwell scale, roughly 60-61 HRC. It holds an edge better than S30V while maintaining a fine steel grain. This allows the steel to remain sharp longer, but comes at the cost of it being harder to sharpen.

This steel is prone to chipping due to its harder edge and higher edge retention. This mostly comes from the heat treatment of the blade. A good option for very sharp knives if durability is not an issue, CTS-XHP is a newer steel option that favors resistance to corrosion and sharpness.

| Edge Retention | 6/10 |

| Toughness | 5/10 |

| Ease of Sharpening | 6/10 |

| Corrosion Resistance | 7/10 |

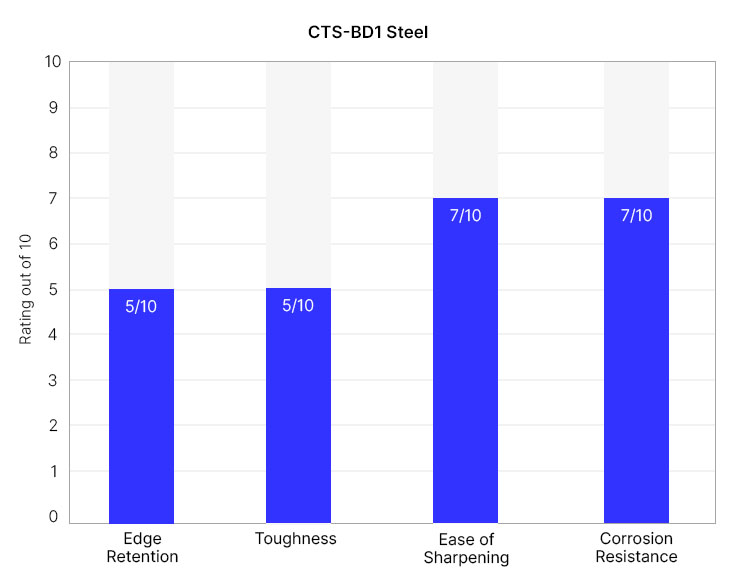

CTS-BD1

An affordable steel that is easy to care for , CTS-BD1 is a good steel for those new to the knife game who want a durable knife that trades off edge retention and toughness for easier sharpening and less chance of corrosion.

| Edge Retention | 5/10 |

| Toughness | 5/10 |

| Ease of Sharpening | 7/10 |

| Corrosion Resistance | 7/10 |

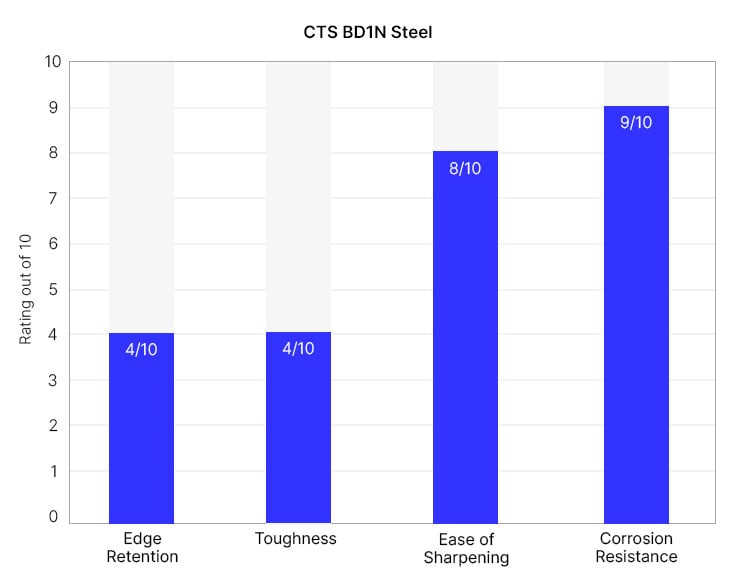

CTS BD1N

This is a newer version of the CTS-BD1 and features additional Nitrogen creating a fine-grained steel. This makes for better edge retention. This steel is another option used by Spyderco for their mid-range folders.

| Edge Retention | 4/10 |

| Toughness | 4/10 |

| Ease of Sharpening | 8/10 |

| Corrosion Resistance | 9/10 |

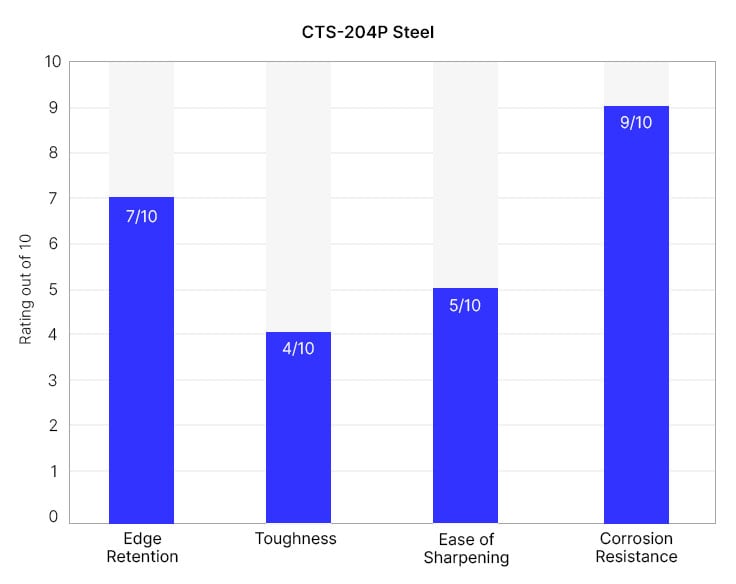

CTS-204P

This is Crucible’s closest equivalent of M390. While it has very similar properties to CPM 20CV it is almost exclusively found in Microtech knives, making it one of the rarer steel types in use.

| Edge Retention | 7/10 |

| Toughness | 4/10 |

| Ease of Sharpening | 5/10 |

| Corrosion Resistance | 9/10 |

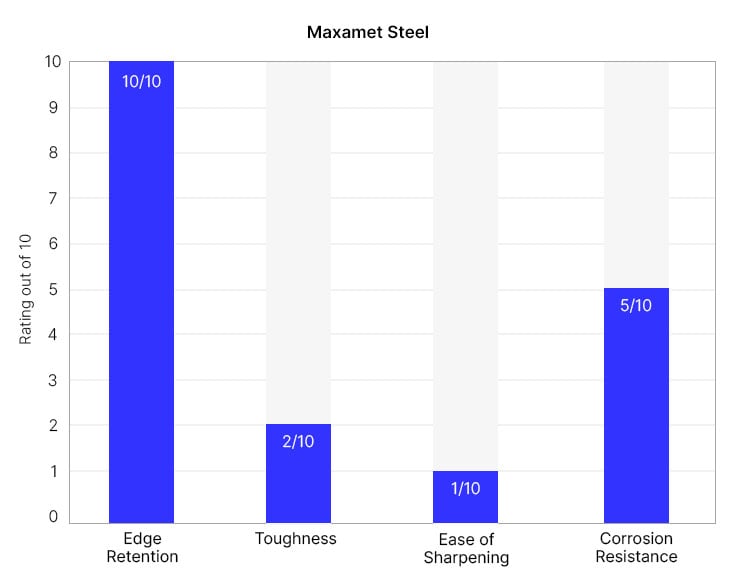

Maxamet

Spyderco is the most prominent user of Maxamet steel. This Micro-Melt steel can produce some of the hardest edges possible with steel.It sacrifices ease of sharpening and durability to maximize edge retention with a moderate degree of corrosion resistance.

| Edge Retention | 10/10 |

| Toughness | 2/10 |

| Ease of Sharpening | 1/10 |

| Corrosion Resistance | 5/10 |

Latrobe Specialty Steel Co

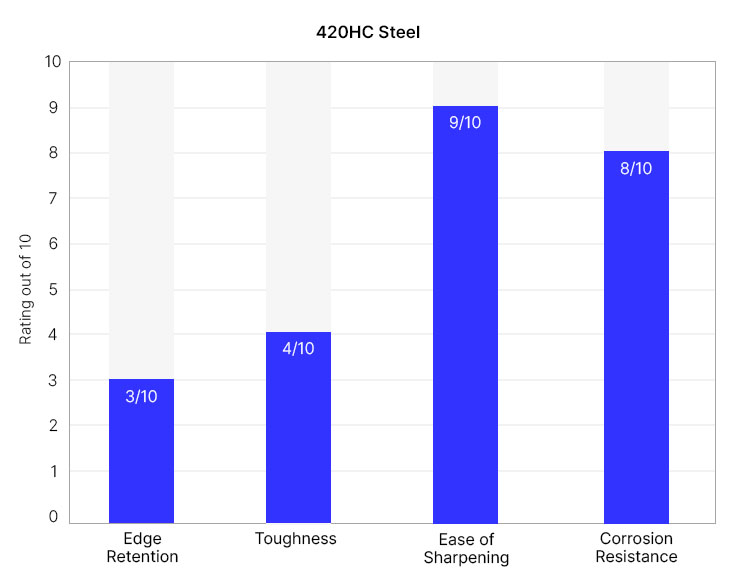

420HC

This is a High Carbon version of 420 stainless steel. The higher carbon content results in more durable edges and a harder steel. Manufacturers like Buck Knives can make the most of the steel with their heat treatment while this steel is still a lower budget steel.

| Edge Retention | 3/10 |

| Toughness | 4/10 |

| Ease of Sharpening | 9/10 |

| Corrosion Resistance | 8/10 |

Swedish Manufactured Steels

Bohler-Uddeholm Steel

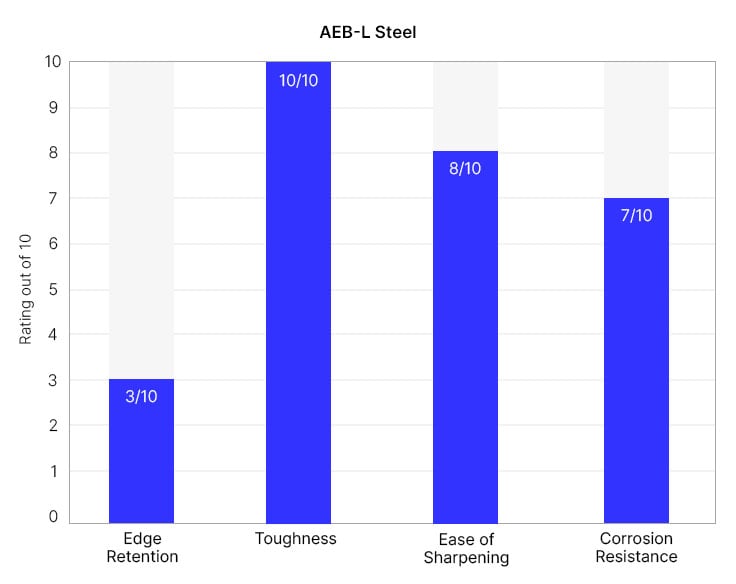

AEB-L

Mostly used by custom makers, this is a fine grained steel known for its toughness. Knives made of AEB-L are incredibly durable. AEB-L is similar to 13C26 and 440A.

| Edge Retention | 3/10 |

| Toughness | 10/10 |

| Ease of Sharpening | 8/10 |

| Corrosion Resistance | 7/10 |

K390

This essentially CPM-10V but manufactured by Bohler instead of Crucible. The steel is able to hold an edge for a long time but stains easily. Predominately used by Spyderco, K390 is harder to sharpen and has average durability.

| Edge Retention | 9/10 |

| Toughness | 5/10 |

| Ease of Sharpening | 3/10 |

| Corrosion Resistance | 4/10 |

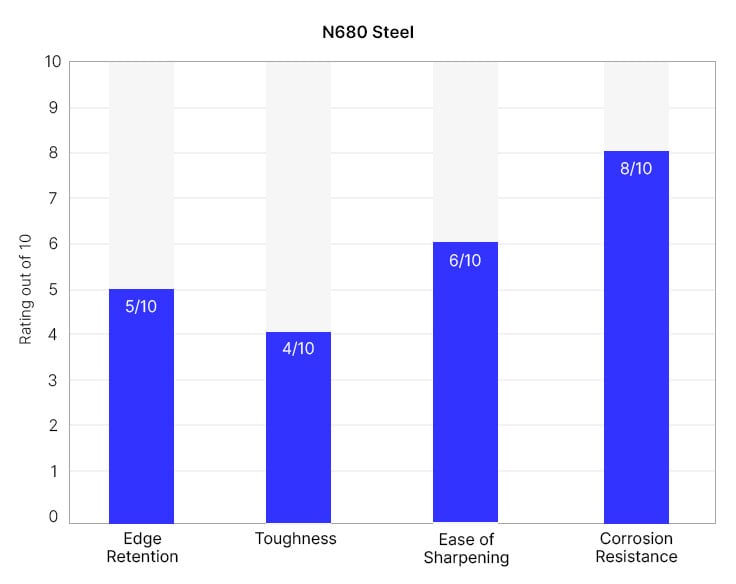

N680

This steel is a cheaper alternative to H1 steels. N680 is 17% chromium with 0.2% nitrogen for better corrosion resistance and toughness. This steel is perfect for saltwater environments or areas of higher corrosion.

| Edge Retention | 5/10 |

| Toughness | 4/10 |

| Ease of Sharpening | 6/10 |

| Corrosion Resistance | 8/10 |

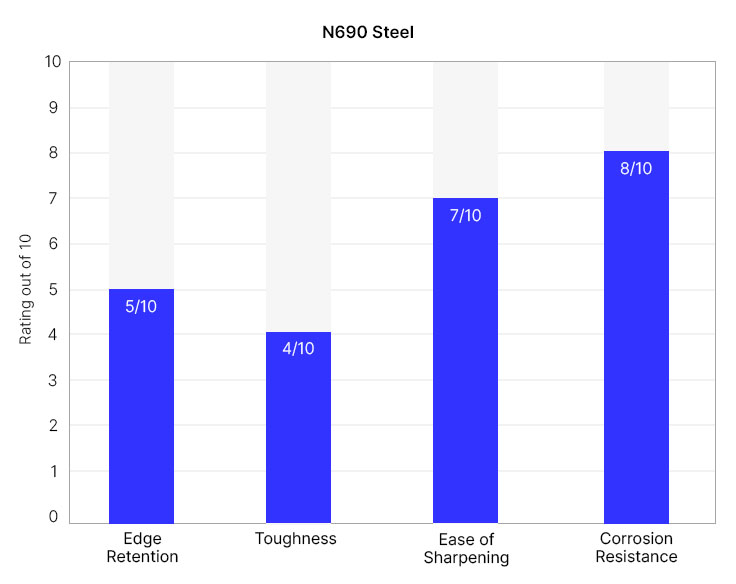

N690

This steel is one of the better options available for budget steels.N690’s good corrosion resistance and ease of sharpening make for a durable knife without having an overly expensive alloy.

| Edge Retention | 5/10 |

| Toughness | 4/10 |

| Ease of Sharpening | 7/10 |

| Corrosion Resistance | 8/10 |

Sandvik Steel

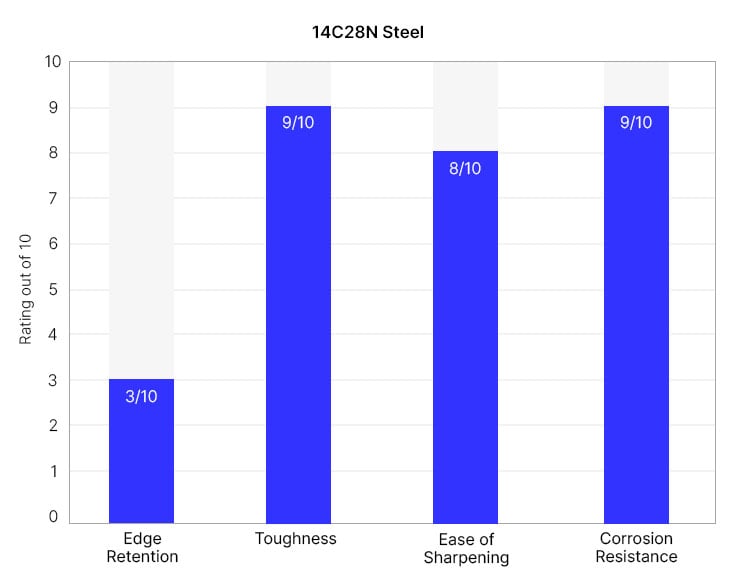

14C28N

This steel is an improvement over 12C26 developed for Kershaw by Sandvik Steel. The improvements mostly focus on better corrosion resistance due to more Nitrogen being added to the steel. This is a good steel for both folding knives and fixed blades that offers relatively good performance, similar to more premium steels.

| Edge Retention | 3/10 |

| Toughness | 9/10 |

| Ease of Sharpening | 8/10 |

| Corrosion Resistance | 9/10 |

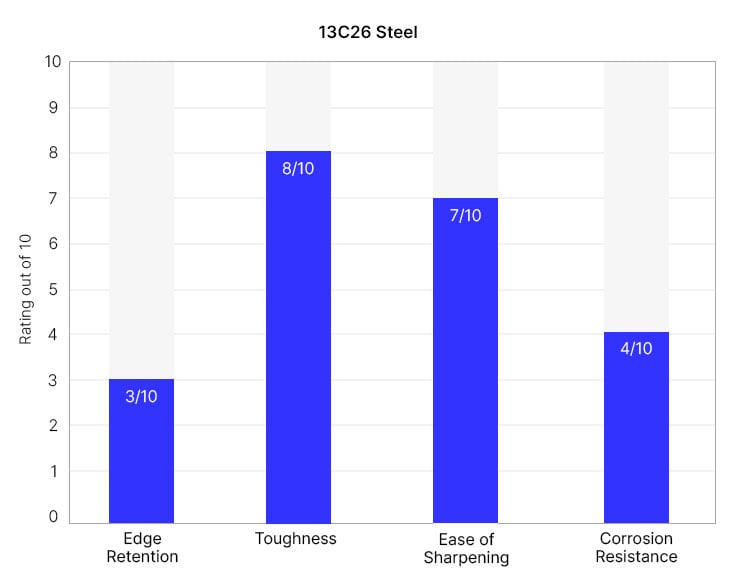

13C26

Sandvik’s equivalent of AEB-L, 13C26 is close to 440A but with a higher ratio of carbon to chromium. This creates a harder material with less corrosion resistance. However this is hard to differentiate during real world use.

| Edge Retention | 3/10 |

| Toughness | 8/10 |

| Ease of Sharpening | 7/10 |

| Corrosion Resistance | 4/10 |

German Manufacturers

Zapp

LC200N

Highly resistant to corrosion, LC200N is used by SPyderco for some of its knives. The steel can hold an edge better than others, but is best used in highly corrosive environments where durability is the primary focus.

| Edge Retention | 3/10 |

| Toughness | 9/10 |

| Ease of Sharpening | 8/10 |

| Corrosion Resistance | 10/10 |

Japanese Manufactured Steels

Hitachi

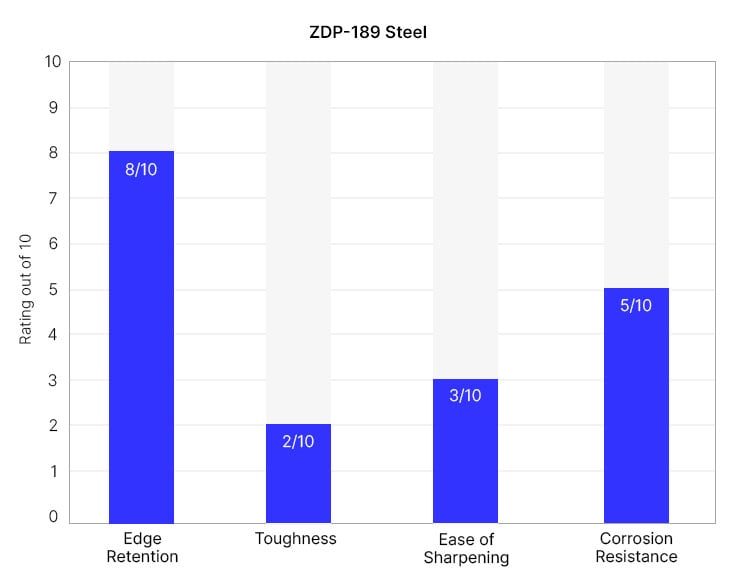

ZDP-189

This steel is mostly used in kitchen knives and can be hardened up to 66 HRC. This makes the steel capable of incredible sharpness but very hard to sharpen. While it does have 20% chromium, this is mostly used to produce carbides. ZDP-189 is more wear resistant than S30V, but corrodes more easily.

| Edge Retention | 8/10 |

| Toughness | 2/10 |

| Ease of Sharpening | 3/10 |

| Corrosion Resistance | 5/10 |

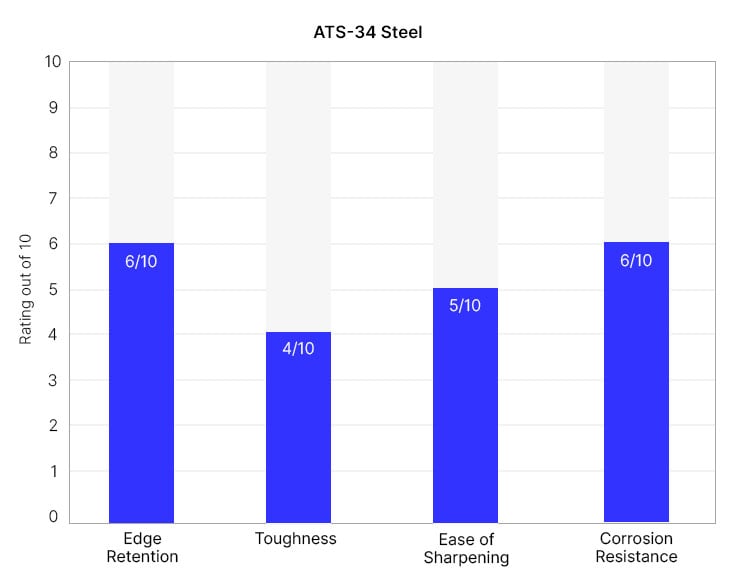

ATS-34

This is the Japanese equivalent of 154CM but is less resistant to corrosion than 440C steels. Despite this, it is very popular among knife makers.

| Edge Retention | 6/10 |

| Toughness | 4/10 |

| Ease of Sharpening | 5/10 |

| Corrosion Resistance | 6/10 |

Myodo Metal

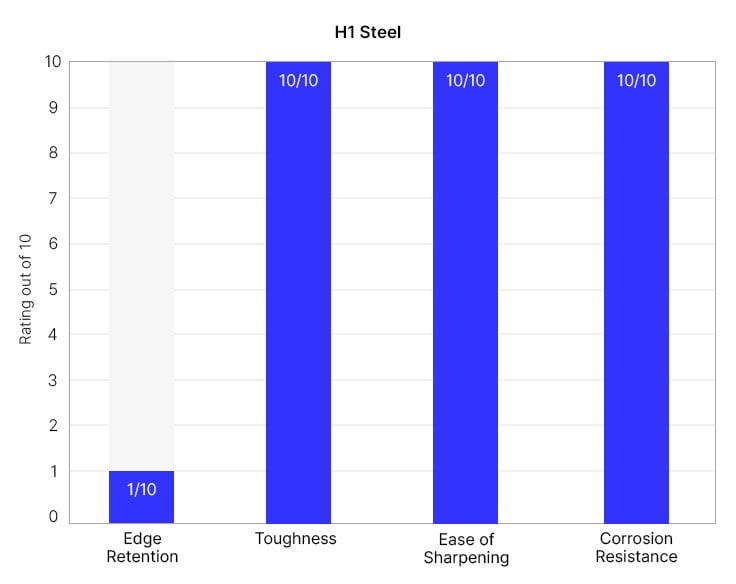

H1

This steel is almost immune to rusting making it perfect for things like dive knives. Incredibly durable and easy to sharpen, the only downsides for this steel are the lack of edge retention and expense. The edge wears away very easily with H1 steel and Spyderco is one of the only manufacturers interest in using this steel for knives.

| Edge Retention | 1/10 |

| Toughness | 10/10 |

| Ease of Sharpening | 10/10 |

| Corrosion Resistance | 10/10 |

Aichi

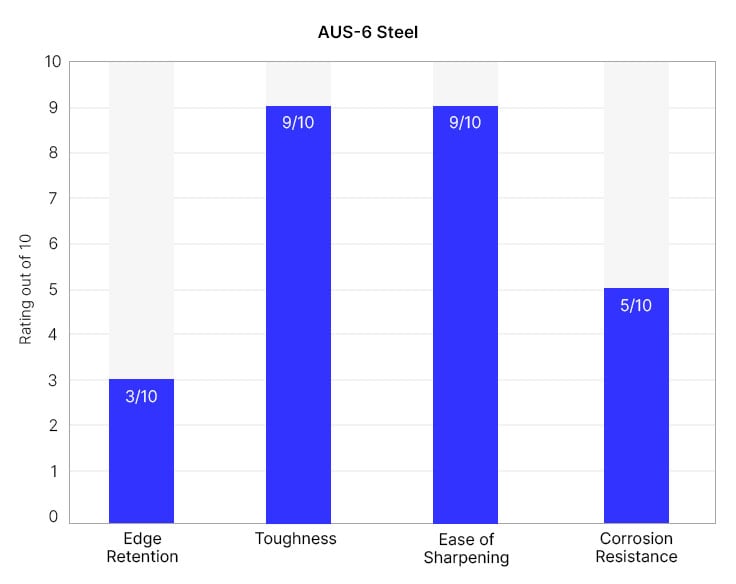

AUS-6

This is the Japanese version of 420 stainless. It has low carbon content but is easy to sharpen and durable. Its corrosion resistance is average.

| Edge Retention | 3/10 |

| Toughness | 9/10 |

| Ease of Sharpening | 9/10 |

| Corrosion Resistance | 5/10 |

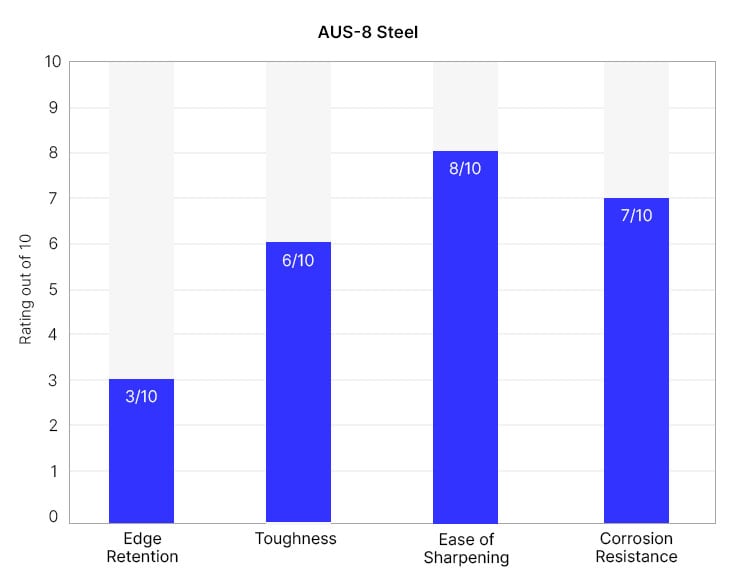

AUS-8

This steel is close to 440B but possesses better corrosion resistance than 440C. It is a common option for beginner knives due to its ease of sharpening and relative durability.

| Edge Retention | 3/10 |

| Toughness | 6/10 |

| Ease of Sharpening | 8/10 |

| Corrosion Resistance | 7/10 |

Takefu Special Steel

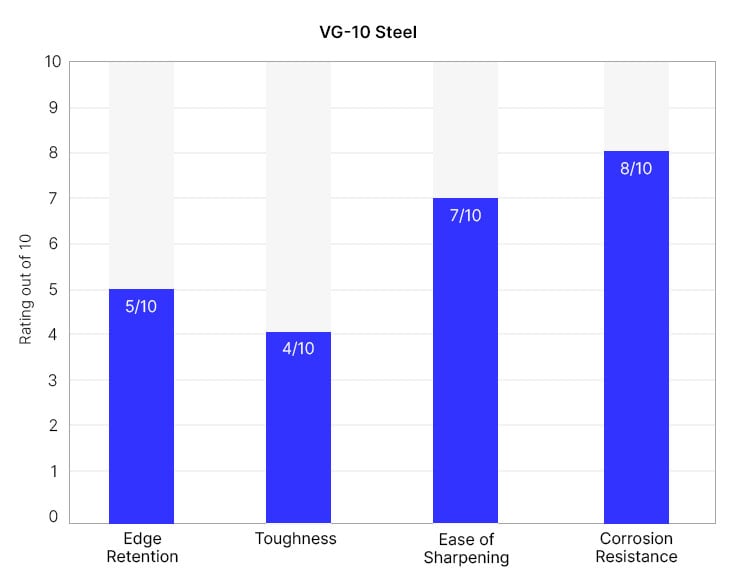

VG-10

This steel is easily cared for and similar to 154CM and ATS-34. It features slightly more chromium in the steel to enhance its corrosion resistance. Commonly used in kitchen knives, it is also used by companies like Spyderco and SOG. VG-10 is sometimes referred to as V-Kin-10.

| Edge Retention | 5/10 |

| Toughness | 4/10 |

| Ease of Sharpening | 7/10 |

| Corrosion Resistance | 8/10 |

Chinese Manufactured Steels

Ahonest

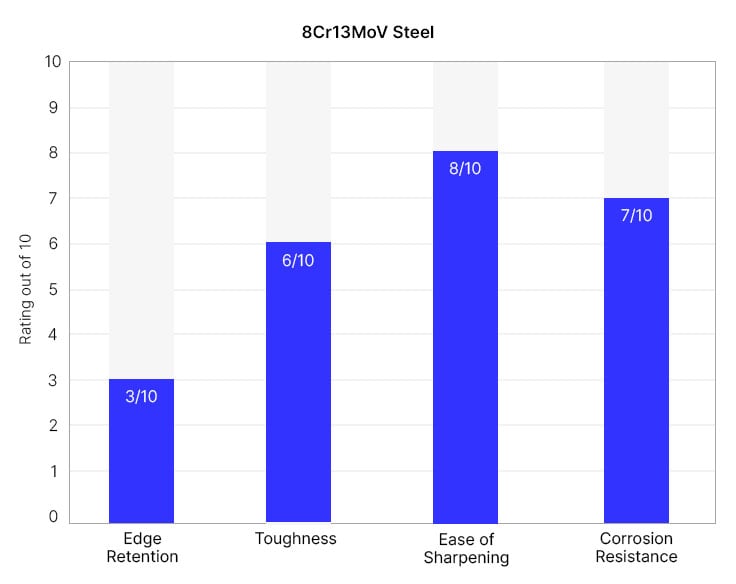

8Cr13MoV

A higher carbon version of AUS-8, 8Cr13MoV is a commonly used budget steel that gets most of its benefits from a proper heat treatment. It is easy to sharpen, relatively tough, resistant to corrosion, and has an acceptable amount of edge retention. All of this combines into a good value of cost and performance.

| Edge Retention | 3/10 |

| Toughness | 6/10 |

| Ease of Sharpening | 8/10 |

| Corrosion Resistance | 7/10 |

Worldwide Production Steels

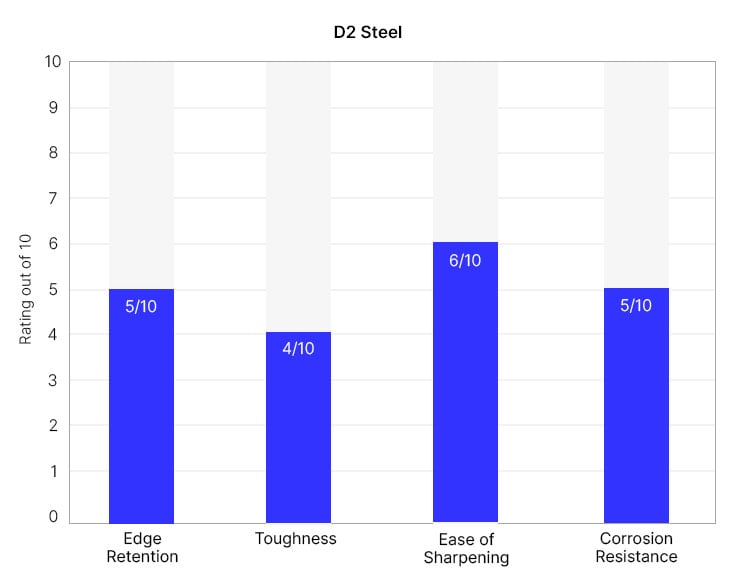

D2

This steel is a semi-stainless option that is a good balance of performance and affordability. While technically stainless, with 12% chromium, it is good with overall average factors. This means the steel is not as susceptible to corrosion, relatively hard to sharpen, retains an edge well, and is moderately durable.

| Edge Retention | 5/10 |

| Toughness | 4/10 |

| Ease of Sharpening | 6/10 |

| Corrosion Resistance | 5/10 |

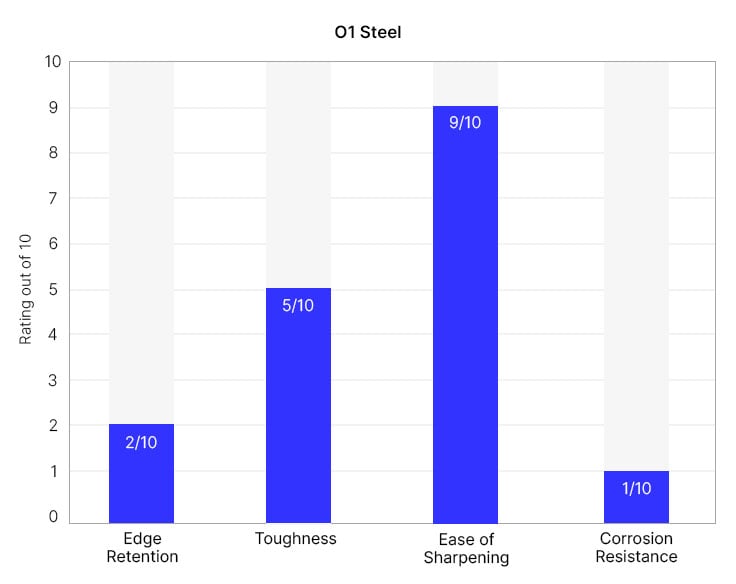

O1

Commonly used for bushcraft knives, O1 tool steel is easy to sharpen and durable. It does not have a lot of resistance to corrosion and it does not hold an edge well. For the style of knives it is used for durability and ease of sharpening take precedence over an edge that can last for a long time.

| Edge Retention | 2/10 |

| Toughness | 5/10 |

| Ease of Sharpening | 9/10 |

| Corrosion Resistance | 1/10 |

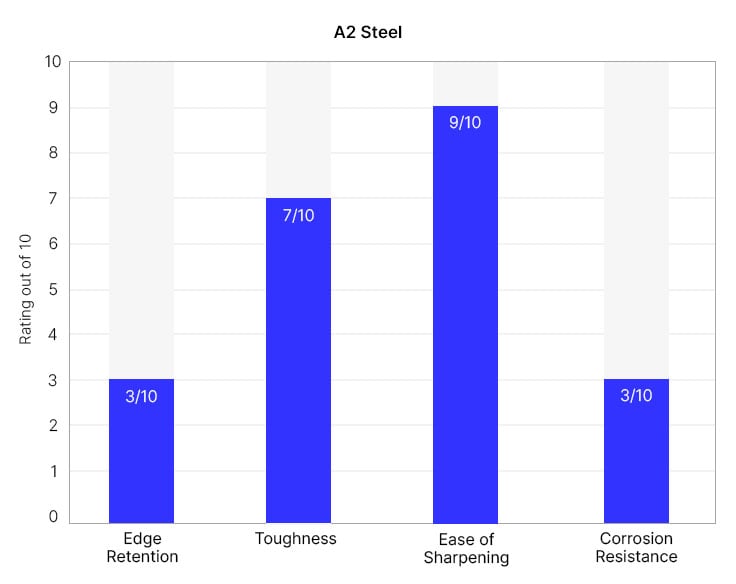

A2

Another bushcraft option, A2 steel is easy to acquire, affordable, and perfect for practicing knife making. It sharpens easily and is very durable which makes it a forgiving steel to new smiths.

| Edge Retention | 3/10 |

| Toughness | 7/10 |

| Ease of Sharpening | 9/10 |

| Corrosion Resistance | 3/10 |

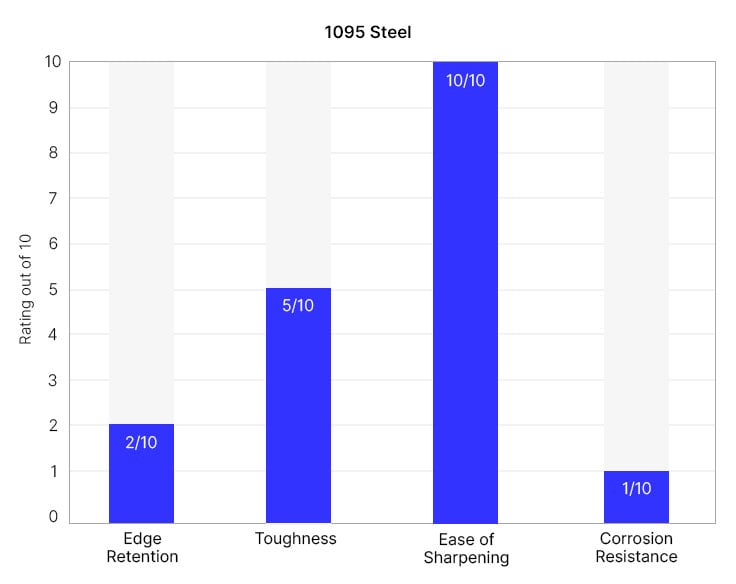

1095

One of the most common types of steel used in knives, 1095 is known for its ease of sharpening and very sharp edges. Another inexpensive option, 1095 is used in survival knives and everything blade size up to swords. Knives made from 1095 are durable but corrode easily. Many manufacturers coat their 1095 steels to reduce corrosion and oil treatment helps prevent rust.

| Edge Retention | 2/10 |

| Toughness | 5/10 |

| Ease of Sharpening | 10/10 |

| Corrosion Resistance | 1/10 |

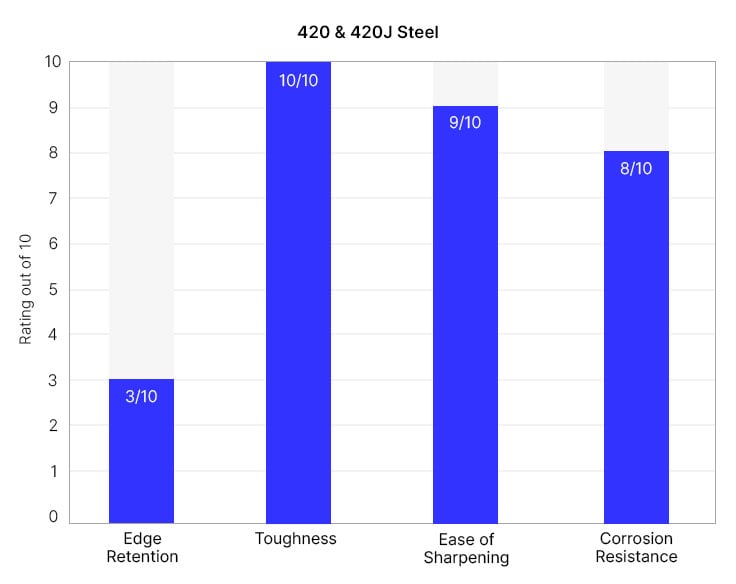

420 & 420J

This style of stainless steel is known for its high levels of durability and resistance to corrosion. It is commonly regarded as being the lowest you can go with stainless steels. The 420 J version is the Japanese equivalent of normal 420 stainless.

| Edge Retention | 3/10 |

| Toughness | 10/10 |

| Ease of Sharpening | 9/10 |

| Corrosion Resistance | 8/10 |

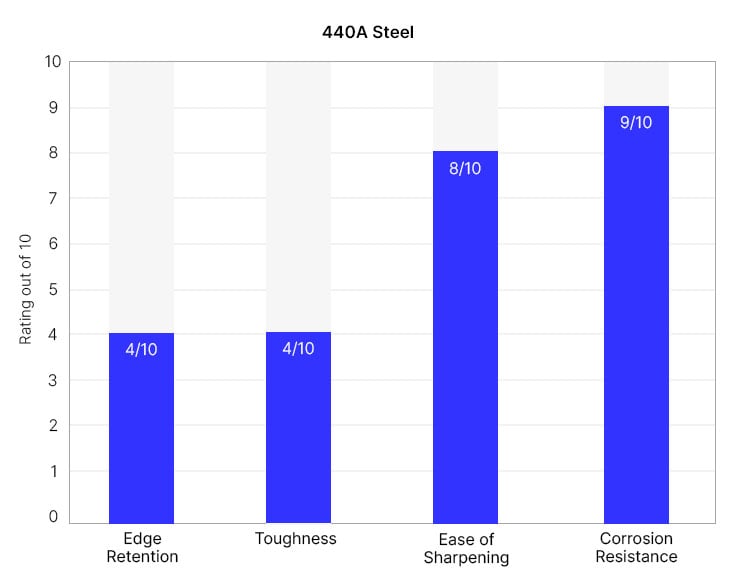

440A

An extremely affordable steel, 440A has a higher carbon content than 420HC. This boosts its wear resistance but lowers its corrosion resistance which is still very high. Easily sharpened, this steel is used for more budget friendly knives.

| Edge Retention | 4/10 |

| Toughness | 4/10 |

| Ease of Sharpening | 8/10 |

| Corrosion Resistance | 9/10 |

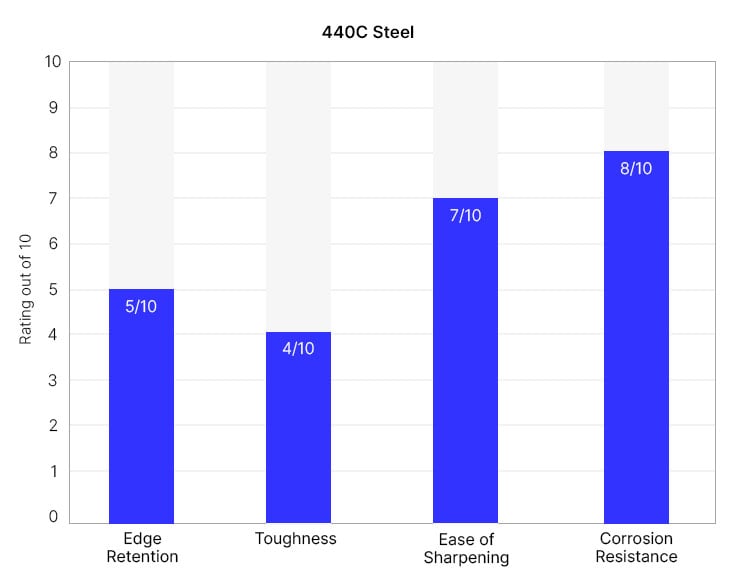

440C

An improved version of 440A, this steel can be used to produce very good knives affordably. It offers better edge retention than 420HC but is less resistant to corrosion. In its steel grade it features some of the highest levels of chromium and carbon.

| Edge Retention | 5/10 |

| Toughness | 4/10 |

| Ease of Sharpening | 7/10 |

| Corrosion Resistance | 8/10 |

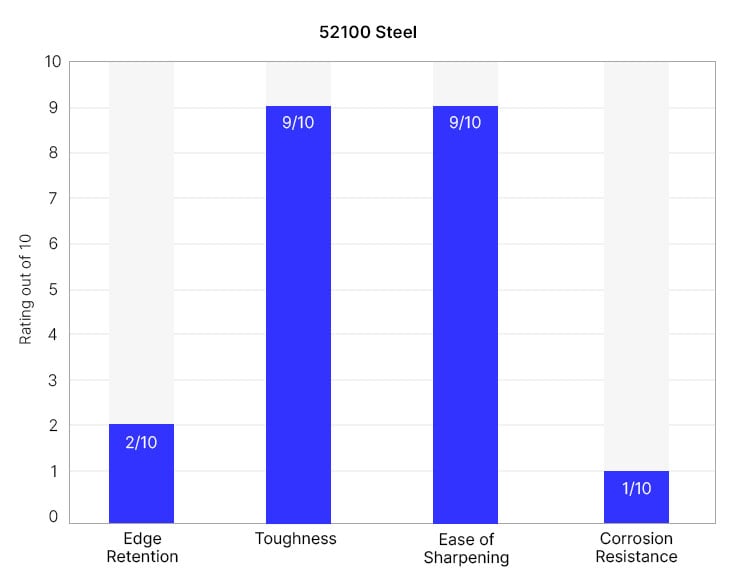

52100

This tough carbon steel was originally designed for ball bearings. This means it has a lot of durability due to it being softer than other steel options. Easy to sharpen, 52100 does not hold an edge well and corrodes very easily. Heat treatment is critical for using this steel.

| Edge Retention | 2/10 |

| Toughness | 9/10 |

| Ease of Sharpening | 9/10 |

| Corrosion Resistance | 1/10 |